The NZ Building Act:

mandatory bad building practices to shorten

the life of your home

Introduction

Today, in New Zealand, housing is being built according to a set of rules with the stated aim of protecting consumers.

Nothing could be further from the truth.

The Building Act is no more than window dressing for a set of rules that vastly increases the cost of building while reducing the lifespan of a building to little more than a throw away consumable.

The Building Act sets out the overall aims and objectives, enforceable by law.

The regulations formed under that Act are supposed to give some guidance as to how those worthy aims might be met.

To the contrary, the regulations illegally create "safe havens" for appallingly bad building products and practices and indemnify the purveyors of said products from being sued when it all hits the fan.

Examples:

Two notable examples are leaky flashings and inadequate bracing. Together these shorten the life of a building by eating away at the structure and creating damage in an earthquake that is so costly to repair that it is cheaper to demolish a house than repair it, at enormous expense to the economy.

Big players in this massive scam on the New Zealand homeowner and taxpayer are the likes of Hardies and Winstones, two organisations without moral compass who, combined with a legislature that is too busy saving face to care about taking any serious action to avert disaster, are hell bent on reducing NZ building stocks to more of a liablility than an asset.

Flashings:

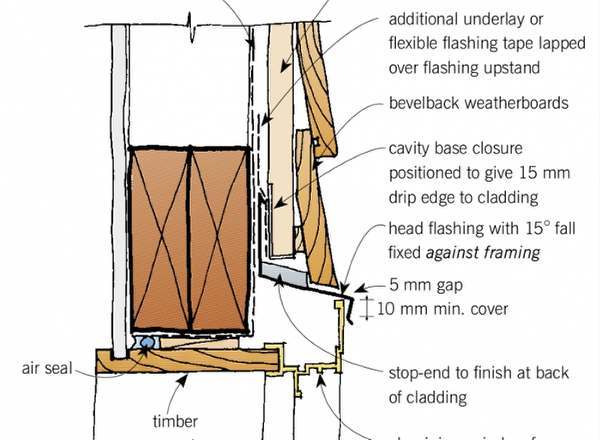

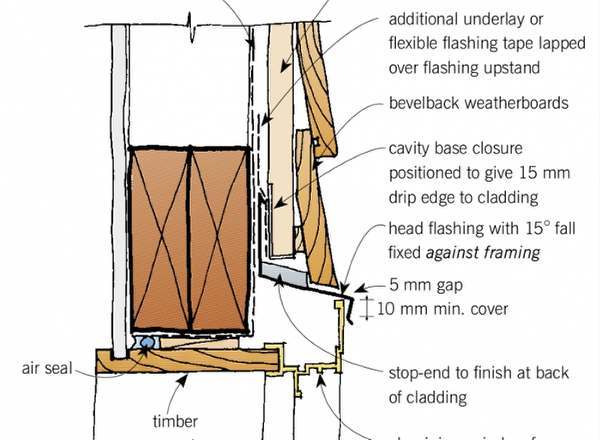

Here is a leaky flashing, courtesy BRANZ I believe (off the Internet), typically used for "Linea Weatherboard," another shonky Hardie's product.

This

detail is the very same detail identified in

the leaky homes scandal as allowing moisture

to sit against timber framing and causing

dry rot.

In a stroke of genius, not, the Branz detail even emphasizes that the flashing should be "against framing."

Instead of changing the detail to something that would work, the regulators in a act of gross stupidity have enshrined this awful detail into law as an "acceptable solution," meaning that local councils who issue building consents will virtually insist that this detail, and this detail alone, will or must be used, even though it leaks, rather that an "alternative" flashing that won't leak.

How does it leak? Weatherboards discharge water to the outside of a building. If you cut a slot or rebate into those boards, they will leak. If you fix flashings to framing, the framing will rot.

I, along with others, have first hand knowledge of the damage caused by these flashings. What first looks to be blistering paint on the outside of a house turns out to be far more extensive once the weatherboards are removed, with rot in lintels, doubled studs, wall framing, bottom plates, and on it goes.

Adding a cavity to let the water "drain out" has to be the dumbest idea yet.

The traditional system, with a proven track record of not leaking, works with the weatherboards, not against them, by discharging moisture to the outside rather allowing it back against the framing.

There is no way any consent authority today is going to allow a traditional flashing. There are no polytechs teaching this correct method. The builders who know how to make a decent flashing are all either retired or have found, like me, that the uphill battle against idiots with excess power and stopwork notices is impossible to win.

Bracing:

In similar fashion to Hardies and their "approved" leaky flashings, Winstone Wallboards would like consumers to believe that using their products to brace a building will make it "safe."

This lie fails to distinguish between bracing and stiffening.

A braced structure is plastic, that is it will deform under load and return to its original shape when the load is removed.

All buildings move to a smaller or greater extent. They move under wind load, earthquake load, heat and cold, and move with the seasons as the ground around the building swells and contracts with moisture. They are supposed to flex.

Traditional bracing holds parts of the building upright. Between braces the building can move whichever way it wants.

Prior to gib linings we had scrim and so on. With the introduction of paperfaced plaster board, builders only nailed sheet edges and intermediates, i.e. only nailed into studs. There was no nailing to either top or bottom plates.

Instead of nailing to the top plate, the scotia was nailed to studs which had the effect of restraining the top edge of gib sheets but still allowed some expansion of the sheet. Similarly the perimeter of the ceiling gib was not nailed, the sheet edges simply resting on the scotia and able to expand and contract.

The bottom edge of gib sheets were not nailed. The skirtings were nailed to studs and this had the effect of constraining the lower edge of gib sheets while still allowing room for the gib to move.

Simple put, wall linings were hung.

In this way bracing kept a building upright and the linings were fixed in a way that allowed for plastic movement. It worked very well.

Today you could not get a consent to do that because these perfectly adequate timber braces are so downgraded by the "rules" as to make it impossible to meet consent requirements.

That downgrading process plays to the advantage of Winstones.

The lie by Winstones is that their products are bracing. They are not.

Sheet products are stiffening and have no ability to behave in a plastic fashion. They are a "use once" product that, having gone through a major earthquake, cannot take the same loads twice. They are throw away products, like the houses they are installed into.

Note:

This page will stay on the web. The Minister for Building and Construction, the Hon Chris Penk, has been advised.

Hardies is James Hardie Industries PLC who operate out of Ireland (and avoid tax in the Netherlands) and have walked away from much of their responsibility for asbestos related deaths caused by a failure to advise consumers of the health risks associated with their asbestos sheet products, and also seem to have walked away from their leaky flashings around Harditex sheet products, a NZ Judge incorrectly finding the problems were related to bad building methods rather than Hardies product failures (how wrong can a person be?). Winstones is owned by Fletchers who just love to hold the building industry to ransom during supply shortages. Thugs, both of them.

Remedy:

At the very least there must be a change to the regulations to make traditional head flashings part of the acceptable solutions and traditional let-in timber bracing (assuming stud sizing of at least 100mm depth to receive them) must be credited with the ability to do the job.

Posted 4th Feb 2024

The bad grammar and typos are all mine. Despite that, I hope the message is clear.

The author is formally qualified with a bachelor's degree in architecture (1980) and a diploma in building surveying (2012).

Today, in New Zealand, housing is being built according to a set of rules with the stated aim of protecting consumers.

Nothing could be further from the truth.

The Building Act is no more than window dressing for a set of rules that vastly increases the cost of building while reducing the lifespan of a building to little more than a throw away consumable.

The Building Act sets out the overall aims and objectives, enforceable by law.

The regulations formed under that Act are supposed to give some guidance as to how those worthy aims might be met.

To the contrary, the regulations illegally create "safe havens" for appallingly bad building products and practices and indemnify the purveyors of said products from being sued when it all hits the fan.

Examples:

Two notable examples are leaky flashings and inadequate bracing. Together these shorten the life of a building by eating away at the structure and creating damage in an earthquake that is so costly to repair that it is cheaper to demolish a house than repair it, at enormous expense to the economy.

Big players in this massive scam on the New Zealand homeowner and taxpayer are the likes of Hardies and Winstones, two organisations without moral compass who, combined with a legislature that is too busy saving face to care about taking any serious action to avert disaster, are hell bent on reducing NZ building stocks to more of a liablility than an asset.

Flashings:

Here is a leaky flashing, courtesy BRANZ I believe (off the Internet), typically used for "Linea Weatherboard," another shonky Hardie's product.

In a stroke of genius, not, the Branz detail even emphasizes that the flashing should be "against framing."

Instead of changing the detail to something that would work, the regulators in a act of gross stupidity have enshrined this awful detail into law as an "acceptable solution," meaning that local councils who issue building consents will virtually insist that this detail, and this detail alone, will or must be used, even though it leaks, rather that an "alternative" flashing that won't leak.

How does it leak? Weatherboards discharge water to the outside of a building. If you cut a slot or rebate into those boards, they will leak. If you fix flashings to framing, the framing will rot.

I, along with others, have first hand knowledge of the damage caused by these flashings. What first looks to be blistering paint on the outside of a house turns out to be far more extensive once the weatherboards are removed, with rot in lintels, doubled studs, wall framing, bottom plates, and on it goes.

Adding a cavity to let the water "drain out" has to be the dumbest idea yet.

The traditional system, with a proven track record of not leaking, works with the weatherboards, not against them, by discharging moisture to the outside rather allowing it back against the framing.

There is no way any consent authority today is going to allow a traditional flashing. There are no polytechs teaching this correct method. The builders who know how to make a decent flashing are all either retired or have found, like me, that the uphill battle against idiots with excess power and stopwork notices is impossible to win.

Bracing:

In similar fashion to Hardies and their "approved" leaky flashings, Winstone Wallboards would like consumers to believe that using their products to brace a building will make it "safe."

This lie fails to distinguish between bracing and stiffening.

A braced structure is plastic, that is it will deform under load and return to its original shape when the load is removed.

All buildings move to a smaller or greater extent. They move under wind load, earthquake load, heat and cold, and move with the seasons as the ground around the building swells and contracts with moisture. They are supposed to flex.

Traditional bracing holds parts of the building upright. Between braces the building can move whichever way it wants.

Prior to gib linings we had scrim and so on. With the introduction of paperfaced plaster board, builders only nailed sheet edges and intermediates, i.e. only nailed into studs. There was no nailing to either top or bottom plates.

Instead of nailing to the top plate, the scotia was nailed to studs which had the effect of restraining the top edge of gib sheets but still allowed some expansion of the sheet. Similarly the perimeter of the ceiling gib was not nailed, the sheet edges simply resting on the scotia and able to expand and contract.

The bottom edge of gib sheets were not nailed. The skirtings were nailed to studs and this had the effect of constraining the lower edge of gib sheets while still allowing room for the gib to move.

Simple put, wall linings were hung.

In this way bracing kept a building upright and the linings were fixed in a way that allowed for plastic movement. It worked very well.

Today you could not get a consent to do that because these perfectly adequate timber braces are so downgraded by the "rules" as to make it impossible to meet consent requirements.

That downgrading process plays to the advantage of Winstones.

The lie by Winstones is that their products are bracing. They are not.

Sheet products are stiffening and have no ability to behave in a plastic fashion. They are a "use once" product that, having gone through a major earthquake, cannot take the same loads twice. They are throw away products, like the houses they are installed into.

Note:

This page will stay on the web. The Minister for Building and Construction, the Hon Chris Penk, has been advised.

Hardies is James Hardie Industries PLC who operate out of Ireland (and avoid tax in the Netherlands) and have walked away from much of their responsibility for asbestos related deaths caused by a failure to advise consumers of the health risks associated with their asbestos sheet products, and also seem to have walked away from their leaky flashings around Harditex sheet products, a NZ Judge incorrectly finding the problems were related to bad building methods rather than Hardies product failures (how wrong can a person be?). Winstones is owned by Fletchers who just love to hold the building industry to ransom during supply shortages. Thugs, both of them.

Remedy:

At the very least there must be a change to the regulations to make traditional head flashings part of the acceptable solutions and traditional let-in timber bracing (assuming stud sizing of at least 100mm depth to receive them) must be credited with the ability to do the job.

Posted 4th Feb 2024

The bad grammar and typos are all mine. Despite that, I hope the message is clear.

The author is formally qualified with a bachelor's degree in architecture (1980) and a diploma in building surveying (2012).

email:

sphlat@actrix.co.nz

.

.